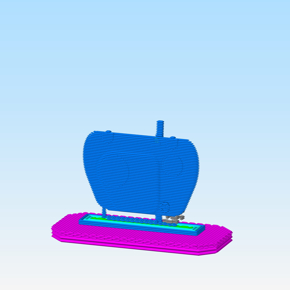

ApolloX Kevlar (ASA)

ApolloX Kevlar is a high-performance aramid fiber reinforced ASA filament. The enhancement with Kevlar results in a shatterproof 3D printing material.

Kevlar does not break and by that greatly improves the impact and damage resistance. ApolloX Kevlar is very easy to 3D print on open desktop machines. No enclosure, or heated chamber is needed! Its low shrinkage factor and perfect layer adhesion make ApolloX Kevlar a breeze to print with.

Important key features

- UV and weather resistant

- Reinforced with 10% Kevlar

- heat resistant up to 94°C

- High damage, impact, and fatigue resistance

- Easy to print on open desktop 3D printers

Suitable applications

- Automotive parts

- Robotics and drones

- Fixtures, tooling, work holding, and soft jaws

- Protective gear

- Manufacturing end-use products

Aramid (Kevlar) fiber reinforcement explained

Reinforcing filaments with aramid fibers – or Kevlar – results in great benefits. It combines the unique properties

of both materials. The properties of the thermoplastic improve with everything Kevlar offers. Kevlar offer lots

of benefits, such as:

- Very high strength-to-weight ratio

- Increasing impact strength

- Reducing weight

- Increasing tensile strength

- Increasing dimensional stability

- Reducing shrinkage / warping

- Increasing chemical resistance

- Increasing heat resistance

- Masking layer lines with a matt surface finish in 3D printed objects

This makes Kevlar reinforced filaments perfect for 3D printing durable parts that will not break easily.