iglidur i150 се характеризира с висока износоустойчивост, тъй като материалът е обогатен с твърди смазочни вещества. Може да се обработва също толкова лесно, колкото стандартните PLA и PETG филаменти. Благодарение на високата си износоустойчивост и добрите механични свойства (якост, жилавост, адхезия на слоевете), той е универсален материал, подходящ за повечето приложения и 3D принтери. Това го прави най-често използваният филамент igus. Има ограничения само по отношение на максималната постоянна температура на приложение от 65 °C и за силно динамични приложения. Освен това, той е подходящ за контакт с храни поради съответствието с EU 10/2011 и следователно е идеален за приложения в хранително-вкусовата промишленост и опаковъчната промишленост. Със свързващото вещество igus за трибофиламенти, iglidur i150 може да се обработва върху конвенционално печатащо легло (напр. стъкло).

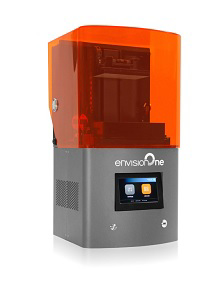

Максимален експлоатационен живот: превъзходна функционалност, сега и в страхотен външен вид!

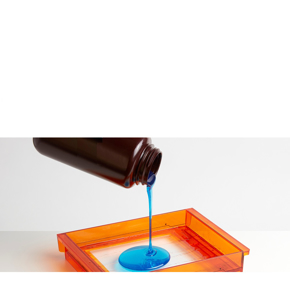

В отговор на многобройното търсене, вече предлагаме нашия популярен и лесен за обработка трибофиламент iglidur i150 в бял вариант. Материалът впечатлява с отлично повърхностно покритие и следователно е подходящ и за сложни видими части, които по никакъв начин не са по-лоши от частите, изработени от познатия трибофиламент i150.

Забележка: Съответствието с храните съгласно EU 10/2011 се отнася само за iglidur i150 в бяло, но работим и върху сертифицирането за черния вариант.

Печат на широкоформатни компоненти от iglidur i150?

iglidur i150 се предлага и на ролка от 2 кг: По този начин смяната на ролката вече не е необходима при 3D печат на особено големи или множество компоненти в един процес на печат и се произвежда по-малко остатъци от филамент. За по-голяма производителност при 3D печат!

Кога да го използвате?

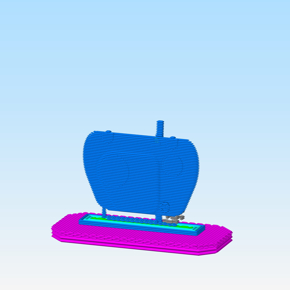

За приложения с ниски или средни скорости на повърхността (безопасно до 0,2 м/с, тествайте за по-високи скорости) Ако търсите лесен за обработка трибофиламент, който може да се обработва на всеки 3D принтер Ако приложението изисква материал за хранителни цели Ако имам 3D принтер без нагрято печатащо легло Ако трябва да се отпечатват много големи компоненти с размер до 3 метра