Кошница

Търси

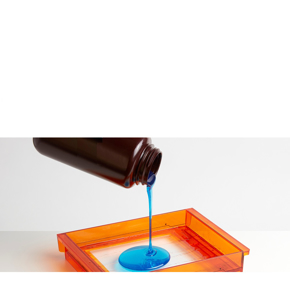

TPU

BIGREP TPU BLACK

186,18 лв. / 95,19 €

BigRep TPU opens up a wealth of possibilities for manufacturers and consumers with a flexible engineering-grade material that has been expertly developed and tested to work with BigRep’s large-format industrial 3D printers.

BIGREP TPU RED

186,18 лв. / 95,19 €

BigRep TPU opens up a wealth of possibilities for manufacturers and consumers with a flexible engineering-grade material that has been expertly developed and tested to work with BigRep’s large-format industrial 3D printers.

MD FLEX - Grey Blue

155,51 лв. / 79,51 €

Copper 3D MDFlex is an innovative Nanocomposite 3D printer filament developed with proven high-quality Python Flex TPU compound and a patented, scientifically validated and highly effective Nano-Copper additive. This unique combination of technologies brings the following characteristics to MDFlex.

MD FLEX - Red

155,51 лв. / 79,51 €

Copper 3D MDFlex is an innovative Nanocomposite 3D printer filament developed with proven high-quality Python Flex TPU compound and a patented, scientifically validated and highly effective Nano-Copper additive. This unique combination of technologies brings the following characteristics to MDFlex.

NT Armadillo Fire

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Armadillo Flamingo

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Armadillo Grass

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Armadillo Lava

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Armadillo Midnight

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Armadillo Sapphire

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Armadillo Snow

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Armadillo Steel

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Armadillo Sun

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Armadillo Water

99,60 лв. / 50,92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

NT Cheetah Fire

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Flamingo

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Grass

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Lava

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Midnight

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Neon

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Sapphire

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

TPU

Filter by:

Clear All