Кошница

Търси

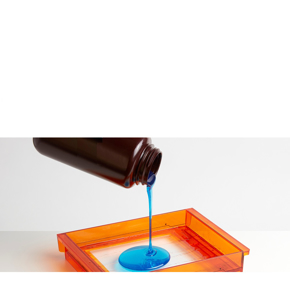

Flexible materials

NT Cheetah Midnight

99,60 лв. / 50,92 €

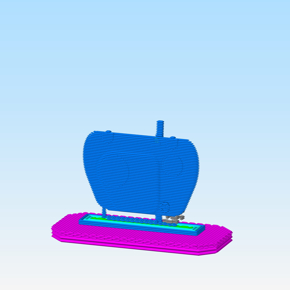

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Neon

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Sapphire

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Snow

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Steel

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

NT Cheetah Sun

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

NT Cheetah Water

99,60 лв. / 50,92 €

Cheetah™ flexible filament is the fastest and easiest to print flexible filament on the market. The focus in development of this material was on optimizing the user experience. The result is a filament that is printable across all types of desktop 3D printers at ABS and PLA speeds, many times twice the speed of other flexible materials on the market.

Cheetah filament possesses industry leading durability along with impact strength 84% greater than the next product(ABS). The abrasion resistance is also second only to NinjaTek’s Armadillo product, making Cheetah the perfect blend of speed, toughness and strength.

Suggested Applications: grips, guides, hinges, sleeves & snap-fit parts.

Shore Hardness = 95A

Prints at speeds greater than 60 mm/s with standard ABS settings

Significantly greater impact strength than all widely used materials – 84% greater than ABS!

Industry leading toughness and durability to ensure longevity in printed parts

Abrasion resistance 40% better than ABS and 76% better than PLA

580% elongation capabilities improve ability to withstand wear and tear

Patented low friction exterior allows for smooth feeding

Chemical resistance to many materials, including: naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

REACH and RoHS 2002/95/EC Directive compliant

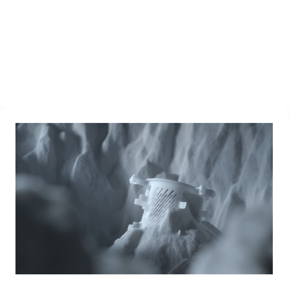

NT EEL Midnight

213,44 лв. / 109,13 €

Eel 3D printing filament is NinjaTek’s first truly conductive, flexible filament.

Eel’s 355% elongation allows for repeated movement without wear or cracking. You’ll produce reliable, high quality prints due to the consistent diameter. NinjaTek’s Eel filament is chemical resistant to a variety of materials.

Python Flex TPU 90A - Black

74,40 лв. / 38,04 €

Python Flex TPU 90A е много гъвкав тип филамент за 3D принтер с твърдост по Шор 90A и е перфектен за 3D отпечатване на здрави и еластични части, които изискват както гъвкавост, така и еластичност.

Python Flex TPU 90A - Clear

74,40 лв. / 38,04 €

Python Flex TPU 90A е много гъвкав тип филамент за 3D принтер с твърдост по Шор 90A и е перфектен за 3D отпечатване на здрави и еластични части, които изискват както гъвкавост, така и еластичност.

Python Flex TPU 90A - Skin Tone ID10

74,40 лв. / 38,04 €

Python Flex TPU 90A е много гъвкав тип филамент за 3D принтер с твърдост по Шор 90A и е перфектен за 3D отпечатване на здрави и еластични части, които изискват както гъвкавост, така и еластичност.

Python Flex TPU 90A - Skin Tone ID2

74,40 лв. / 38,04 €

Python Flex TPU 90A е много гъвкав тип филамент за 3D принтер с твърдост по Шор 90A и е перфектен за 3D отпечатване на здрави и еластични части, които изискват както гъвкавост, така и еластичност.

Python Flex TPU 90A - Skin Tone ID4

74,40 лв. / 38,04 €

Python Flex TPU 90A е много гъвкав тип филамент за 3D принтер с твърдост по Шор 90A и е перфектен за 3D отпечатване на здрави и еластични части, които изискват както гъвкавост, така и еластичност.

Python Flex TPU 90A - Skin Tone ID6

74,40 лв. / 38,04 €

Python Flex TPU 90A е много гъвкав тип филамент за 3D принтер с твърдост по Шор 90A и е перфектен за 3D отпечатване на здрави и еластични части, които изискват както гъвкавост, така и еластичност.

Python Flex TPU 90A - Skin Tone ID8

74,40 лв. / 38,04 €

Python Flex TPU 90A е много гъвкав тип филамент за 3D принтер с твърдост по Шор 90A и е перфектен за 3D отпечатване на здрави и еластични части, които изискват както гъвкавост, така и еластичност.

Python Flex TPU 90A - White

74,40 лв. / 38,04 €

Python Flex TPU 90A е много гъвкав тип филамент за 3D принтер с твърдост по Шор 90A и е перфектен за 3D отпечатване на здрави и еластични части, които изискват както гъвкавост, така и еластичност.

ReForm rTPU 85A - Traffic Black

58,09 лв. / 29,70 €

Гъвкав и устойчив TPU филамент за 3D печат

ReForm rTPU 85A - Traffic White

58,09 лв. / 29,70 €

Гъвкав и устойчив TPU филамент за 3D печат

ReForm rTPU 90A - Traffic Black

58,09 лв. / 29,70 €

Полугъвкав и устойчив TPU филамент за 3D печат

ReForm rTPU 90A - Traffic White

58,09 лв. / 29,70 €

Полугъвкав и устойчив TPU филамент за 3D печат

ReForm rTPU 95A - Traffic Black

58,09 лв. / 29,70 €

Медиум, гъвкав и устойчив избор за филамент за 3D печат на TPU