Кошница

Търси

NGEN_FLEX

NGEN_FLEX DARK GRAY

93,96 лв. / 48,04 €

nGen_flex dark gray.

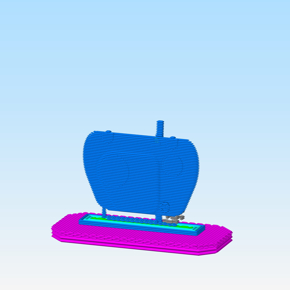

nGen_FLEX is best described as a semi-flexible material with good printability on most 3D printers eliminating the use for specialized flex extruders. It’s rated at a Shore A hardness level of 95. By adjusting infill and perimeter settings it’s possible to influence how flexible a part should feel after printing.

nGen_FLEX is processed at 240C/260C on most 3D printers.

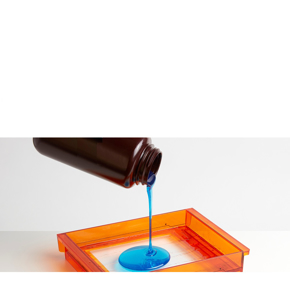

! For best adhesion to the buildplate we highly recommend to use a buildTak plate.

NGEN_FLEX BLACK

93,96 лв. / 48,04 €

nGen_flex beautiful glossy black.

nGen_FLEX is best described as a semi-flexible material with good printability on most 3D printers eliminating the use for specialized flex extruders. It’s rated at a Shore A hardness level of 95. By adjusting infill and perimeter settings it’s possible to influence how flexible a part should feel after printing.

nGen_FLEX is processed at 240C/260C on most 3D printers.

! For best adhesion to the buildplate we highly recommend to use a buildTak plate.

NGEN_FLEX CLEAR

93,96 лв. / 48,04 €

nGen_FLEX is a new elastomer material added to our existing range of co-polyester functional 3D printing filaments.

nGen-FLEX is best described as a semi-flexible material with good printability on most 3D printers eliminating the use for specialized flex extruders. It’s rated at a Shore A hardness level of 95.. Of course the user can influence how flexible a print should feel by adjusting infill and perimeter settings.

nGen_FLEX is an engineering-grade material that demonstrates excellent durability, toughness and great layer-to-layer adhesion.

What makes nGen_FLEX standout from other semi-flexible materials is the great chemical resistance and temperature resistance of up to 121C. Enabling parts to be steam sterilized at 123C cycle.

! For best adhesion to the buildplate we highly recommend to use a buildTak plate.