Кошница

Търси

IGUS

IGUS IGLIDUR I150

133,31 лв. / 68,16 €

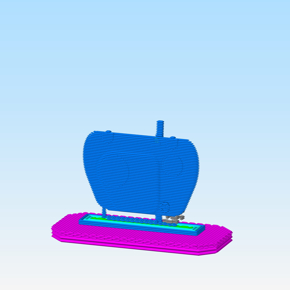

Компонентите, изработени от igus® Tribo-Filament, са до 50 пъти по-устойчиви на износване от стандартните материали за 3D печат и следователно имат изключително дълъг експлоатационен живот. Благодарение на отличните си трибологични свойства, те са подходящи за 3D печат на резервни части, например лагери, задвижващи гайки, зъбни колела и други износващи се части. igus® Tribo-Filament могат да се обработват на 3D принтери, базирани на метода на моделиране чрез стопяване и отлагане (FDM/FFF) и позволяващи регулиране на температурата на дюзата според нуждите.

IGUS IGLIDUR I180

179,13 лв. / 91,59 €

Components made of igus® Tribo-Filament are up to 50 times more wear-resistant than standard materials for 3D printing and therefore have an extremely long service life. Due to their excellent tribological

properties, they are suited for 3D printing of replacement parts, for example bearings, drive nuts, gears and other wear parts. The igus® Tribo-Filaments can be processed on 3D printers that are based on the fused-deposition-modelling method (FDM/FFF) and that allow the nozzle temperature to be set as required.

IGUS IGLIDUR I180-BL

179,13 лв. / 91,59 €

Components made of igus® Tribo-Filament are up to 50 times more wear-resistant than standard materials for 3D printing and therefore have an extremely long service life. Due to their excellent tribological

properties, they are suited for 3D printing of replacement parts, for example bearings, drive nuts, gears and other wear parts. The igus® Tribo-Filaments can be processed on 3D printers that are based on the fused-deposition-modelling method (FDM/FFF) and that allow the nozzle temperature to be set as required.