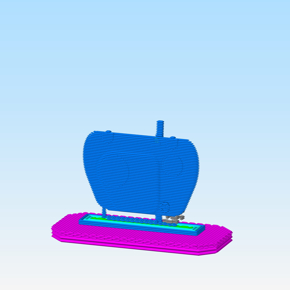

Experimental material.

The material is still in beta, which means we’re still working on the formulation to get the best possible performance. Our current formulation is providing excellent results on 1.75mm direct drive printers, such as the Makerbot Replicator 2 and Prusa I3.

The filament is slightly softer then bronzeFill and copperFill, users need to be careful with applying pressure onto the filament. We’ve found that 3D printers using a bowden tube set-up and 2.85mm filament gives the least reliable results. Users need to take extra care of not over stressing the filament, with pressure and retraction settings.

Like copperFill and bronzeFill the brassFill filament can be post processed. A unique quality of brassFill is the lovely golden shine it shows when polished to perfection.

Adviced 3d printing temperature:

195-220C*

Adviced 3d print speed:

40 - 100 mm/s

Advised Heated bed (if you have one, not strictly necessary)

50-60C

TIP! Depending on your set-up, 3d printer and slice software, you might see that brassFill needs a bit more flow compared to your normal PLA settings. Most plastics will show die swell when coming out of the nozzle tip, this is counteracted with specific slicer settings. Since brassFill doesn’t show a die swell such as PLA you might need to increase flow rate a bit, 4-8% was perfect for our UM2. UM original did not need any adjustments.

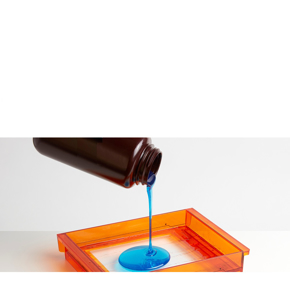

TIP! Sanding and polishing your parts will make the brass particles shine. Start sanding with grit 120-180 and make sure all the printed lines vanish. You’ll notice that because brassFill is easy to sand down, careful you won’t loose too much detail. Then start working your way up by following with grit 240-320 and finishing off with grit 600 - or higher. Finally we used a clean soft cloth and some brass polish to really get all of the shine out of the brass particles.

General Tips

Build platform

Our PLA/PHA compound performs well on both heated and non-heated build platforms. For those users printing on a cold build platform we advise applying masking tape to the build area. The rough surface of the tape will provide enough adhesion for the first layer to stick and print almost without any warping.

Users using heated build platforms have quite a few options these days. The usual suspects are glass and aluminum build plates. For directly printing on glass or aluminum we advice user to apply glue-stick. A very thin layer will be sufficient to keep your print nicely in place. Another method is dissolving wood glue in water, you the consistency of the substance can be quite thin, a bit like milk. By applying just a few drops and smearing this out before you start heating the built plate will create a very thing layer which holds the woodFill down very well. If applying this method, be careful that you don’t get your electronics wet.

Another method that works well with colorFabb woodFill is polyimide tape, or Kapton tape. This tape is available as a very narrow strip or very wide strips which allow you to cover the build plate in one go. When the tape is applied correctly it can last for months.

TIP! Take your time leveling the bed and adjusting the the gap between 3d printer nozzle and build plate. A perfect first layer will is very important, especially for 3d prints with a large bottom layer. Having the nozzle set to close to the build plate will cause a pressure build up and as a result back flow in most hot ends.

TIP! PLA/PHA has very minimal warping tendencies, however if your printing parts which take up the maximum of you buildspace you might see some warping. If it’s very important that your part is perfectly flat than we suggest to turn down the fan that is cooling your part. This allows the material to slowly get rid of heat without warping. After a few centimeters you can turn on the cooling if the part needs it.

*3d printers have lots of different types of hot-end which makes it extremely difficult to give aan temperature advice. We feel our temperature advice holds for most 3d printers, but should be considered as a starting point for you to find the temperatures that work in you setup. Don’t be afraid to go either higher or lower then our advised temperatures if you feel your set-up needs this.

Material:

colorFabb brassFill - PLA/PHA + fine brass powder

Diameter Tolerance:

± 0.05 mm

Density:

3.9 g·cm-3

Glass Transition Temperature

55C