Shopping cart

Search

DLP Resins

Easy Cast 2.0 C

850,00 лв. / 434.60 €

Castable • High Speed • Jewelry

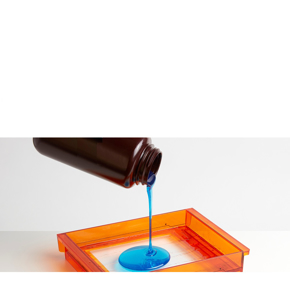

Easy Cast 2.0 C is a breakthrough material for the high-speed printing of a castable models. Easy Cast 2.0 C is a photopolymer with the highest wax content available in 3D printing today.

Easy Cast 2.0 C was developed for printing exclusively on EnvisionTEC’s patented cDLM printers. Because cDLM technology has almost zero separation forces during printing, it allows for 90% liquid wax content in the formulation. Consequently, patterns printed in Easy Cast 2.0 C feature burnout similar to injection wax.

What’s more, because of the addition of special hardeners, Easy Cast 2.0 C still delivers exceptional crisp features, similar to EnvisionTEC’s low- and no-wax materials — from the smallest of pierced filigrees to the sharpest of corners on raised surfaces.

Easy Cast 2.0 C, launched in 2017, sets a new standard in castable 3D printed materials.

EC 3000

700,00 лв. / 357.90 €

Castable • Jewelry

EC3000 has been a popular material in EnvisionTEC’s Easy Cast or “EC” material lineup for more than a decade. Our EC materials are known for higher wax content, less thermal expansion during burnout and foolproof casting.

With a 55% wax content material, including both liquid and and powder wax, EC3000 is the highest wax material EnvisionTEC offers for printing on its non-continuous DLP printers. Any higher wax content requires printing on cDLM technology with Easy Cast 2.0 C.

EC3000 delivers exceptionally crisp detail and a smooth surface finish, along with the clean burnout that delivers foolproof casting with standard investments.

EC500

850,00 лв. / 434.60 €

CASTABLE • JEWELRY

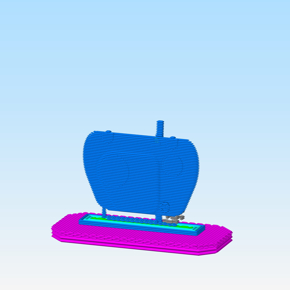

EC500 is part of EnvisionTEC’s Easy Cast or “EC” material lineup, and is recommended for heavier jewelry pieces up to 20 grams finish weight. Our EC materials are known for higher wax content, less thermal expansion during burnout and foolproof casting.

With 20% wax content, EC500 is the highest resolution and crispest lost wax casting material without sacrificing the speed of higher plastic materials. EC500 can be used on EnvisionTEC’s DLP desktop and Perfactory printers.

EC500 has a melting point of 250 degrees C, and zero ash content on complete burnout, which allows for easy casting.

E-OrthoShape

360,00 лв. / 184.07 €

E-OrthoShape is a grey ABS-like material that prints in 100 micron layers. It is recommended for the affordable volume production of models on which to produce clear thermoformed aligners by orthodontic professionals.

E-Partial

1 080,00 лв. / 552.20 €

Castable • Dental

A castable material developed for a specific need in the dental industry: delivering delicate partial frameworks with thin features and some flexibility for casting.

E-Partial material maintains flexural strength to ensure clasp flex without breakage. The stiffness of E-Partial allows for production of a very hard retention grid and super tight thin clasps to deliver a metal partial with the perfect fit every time.

Importantly, E-Partial can be printed at a 25 micron resolution in the Z axis, for extreme accuracy.

EPIC

780,00 лв. / 398.81 €

Castable • Jewelry

EPIC is an Exceptional Plastic Investment Casting material. It is highly recommended for special order retail and other jewelry customers who require flexibility between large and small pieces and have expert-level quality control in casting.

A low-wax 3D printing material, containing 8% liquid wax, EPIC delivers results similar to EnvisionTEC’s wax-free PIC material: stiff and crisp details with outstanding surface finish.

While PIC is recommended for delicate pieces up to 5 grams finish weight, such as jewelry pieces, the additional wax gives EPIC additional flexibility up to 12 grams of finish weight. EnvisionTEC recommends casting EPIC with Ransom & Randolph’s PlastiCast PT or other extra-high-strength investments.