Shopping cart

Search

ColorFABB

NGEN_FLEX CLEAR

93,96 лв. / 48.04 €

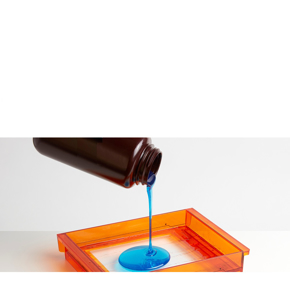

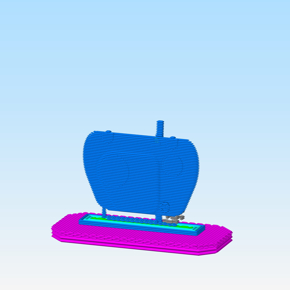

nGen_FLEX is a new elastomer material added to our existing range of co-polyester functional 3D printing filaments.

nGen-FLEX is best described as a semi-flexible material with good printability on most 3D printers eliminating the use for specialized flex extruders. It’s rated at a Shore A hardness level of 95.. Of course the user can influence how flexible a print should feel by adjusting infill and perimeter settings.

nGen_FLEX is an engineering-grade material that demonstrates excellent durability, toughness and great layer-to-layer adhesion.

What makes nGen_FLEX standout from other semi-flexible materials is the great chemical resistance and temperature resistance of up to 121C. Enabling parts to be steam sterilized at 123C cycle.

! For best adhesion to the buildplate we highly recommend to use a buildTak plate.

NGEN_FLEX DARK GRAY

93,96 лв. / 48.04 €

nGen_flex dark gray.

nGen_FLEX is best described as a semi-flexible material with good printability on most 3D printers eliminating the use for specialized flex extruders. It’s rated at a Shore A hardness level of 95. By adjusting infill and perimeter settings it’s possible to influence how flexible a part should feel after printing.

nGen_FLEX is processed at 240C/260C on most 3D printers.

! For best adhesion to the buildplate we highly recommend to use a buildTak plate.

NGEN_LUX CHAMPAGNE GOLD

117,48 лв. / 60.07 €

This pale shade of gold reminds of the subtle and unmistakably beautiful color of champagne. It’s elegant and classy and will add instant luxury to any 3D printing project.

NGEN_LUX DIAMOND BLACK

117,48 лв. / 60.07 €

Stylish and luxurious, our Diamond Black looks like diamond dust has used during the production of this filament. A beautiful black is combined with a rich shade of sparkles, resulting in the ultimate black filament.

Night blue RAL 5022

117,48 лв. / 60.07 €

A premium PLA filament, made in the color you want, on demand. Your product will be made within 5-8 business days, other stock products ordered will be shipped once the order is complete.

The color chart is used by colorFabb as a reference. We advise users to do the same when choosing a specific color. Our product images have been carefully made using the same lighting conditions and no post processing. However every screen will produce a slightly different color representation, therefor we do not recommend to base your choice on our product images alone.

NT Armadillo Fire

99,60 лв. / 50.92 €

Tired of fragile 3D printed parts? Armadillo 3D printing filament is a perfect alternative to some of the most common rigid materials on the market.

Made from a specially formulated thermoplastic polyurethane (TPU), its advantages against PLA and ABS lie in its printability and toughness. Armadillo is an excellent material to use for bridging with virtually no warping issues. When you need a rigid product that can withstand wear and tear, Armadillo’s resistance to fracturing makes it a perfect replacement.

Suggested Applications: braces, fasteners, gears and protective covers.

Shore Hardness = 75D

Excellent bridging capabilities and virtually no warping

Abrasion resistance 84% better than PLA and 60% better than ABS

Chemical resistance to many materials, including naphtha, ASTM Oils #1-3, petroleum and freon

Consistent diameter and material properties providing reliable, high quality prints

No heated bed required. Build platform requires same prep as PLA

ColorFABB

Filter by:

Clear All