“Steel yourself”

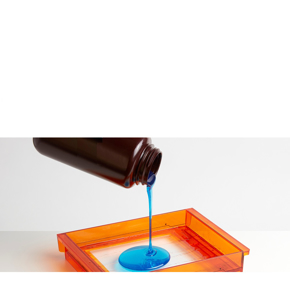

With steelFill we are adding a fourth metal based 3D print filament to our portfolio after succesfully announcing bronzeFill in 2014, copperFill later that year and brassFill in early 2015. As with these other filaments, the key is post-processing and you can use similar techniques as with our other special metal based filaments.

*Steel nozzles

The high steel content of the steelFill material makes this filament quite abrasive to brass nozzles. It’s not as bad as the carbon fiber, XT-CF20 materials, but can effect the print quality after printing 1.5 kg. Therefore it’s recommended to print with abrasive resistant nozzles, for instance the E3D hardened steel nozzle, the JET RSS50 and performance 3-d Hercules nozzles.

Adviced 3d printing temperature:

190-210C*

Adviced 3d print speed:

40 - 80 mm/s

Advised Heated bed (if you have one, not strictly necessary)

50-60C

General Tips

Build platform

Our PLA/PHA compound performs well on both heated and non-heated build platforms. For those users printing on a cold build platform we advise applying masking tape to the build area. The rough surface of the tape will provide enough adhesion for the first layer to stick and print almost without any warping.

Users using heated build platforms have quite a few options these days. The usual suspects are glass and aluminum build plates. For directly printing on glass or aluminum we advice user to apply glue-stick. A very thin layer will be sufficient to keep your print nicely in place. Another method is dissolving wood glue in water, you the consistency of the substance can be quite thin, a bit like milk. By applying just a few drops and smearing this out before you start heating the built plate will create a very thing layer which holds the woodFill down very well. If applying this method, be careful that you don’t get your electronics wet.

Another method that works well with colorFabb woodFill is polyimide tape, or Kapton tape. This tape is available as a very narrow strip or very wide strips which allow you to cover the build plate in one go. When the tape is applied correctly it can last for months.

TIP! Take your time leveling the bed and adjusting the the gap between 3d printer nozzle and build plate. A perfect first layer will is very important, especially for 3d prints with a large bottom layer. Having the nozzle set to close to the build plate will cause a pressure build up and as a result back flow in most hot ends.

TIP! PLA/PHA has very minimal warping tendencies, however if your printing parts which take up the maximum of you buildspace you might see some warping. If it’s very important that your part is perfectly flat than we suggest to turn down the fan that is cooling your part. This allows the material to slowly get rid of heat without warping. After a few centimeters you can turn on the cooling if the part needs it.

*3d printers have lots of different types of hot-end which makes it extremely difficult to give aan temperature advice. We feel our temperature advice holds for most 3d printers, but should be considered as a starting point for you to find the temperatures that work in you setup. Don’t be afraid to go either higher or lower then our advised temperatures if you feel your set-up needs this.

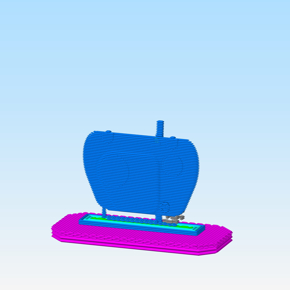

Material:

colorFabb - PLA/PHA + fine steel powder

Diameter Tolerance:

± 0.05 mm

Density:

3,13g/cm3

Glass Transition Temperature

55C