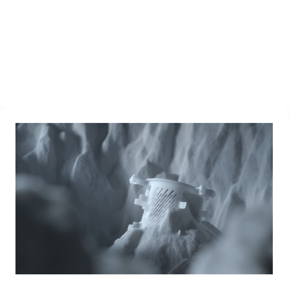

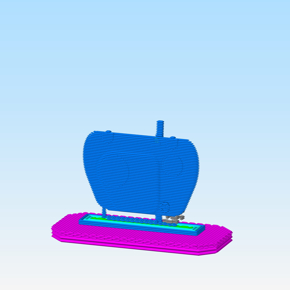

If you’re looking for something special in your filament portfolio then consider our woodFill filament. About 70% colorfabb PLA and 30% recycled woodfibres. Your prints will look absolutely amazing and your 3d printer cave will smell like a woodshop! Check out learn.colorfabb.com for a tutorial and slicer profiles on how to print with woodFill.

Adviced 3d printing temperature:

195-220C*

Adviced 3d print speed:

40 - 100 mm/s

Advised Heated bed (if you have one, not strictly necessary)

50-60C

TIP! For stronger prints and better reliability you can increase flow rate with about 0-10%. This will cause the filament to keep going through the hot zone at a steady pace. Also check out our learn.colorfabb.com website for more information and slicer profiles regarding woodFill.

General Tips

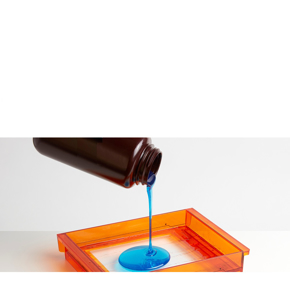

Build platform

Our PLA/PHA compound performs well on both heated and non-heated build platforms. For those users printing on a cold build platform we advise applying masking tape to the build area. The rough surface of the tape will provide enough adhesion for the first layer to stick and print almost without any warping.

Users using heated build platforms have quite a few options these days. The usual suspects are glass and aluminum build plates. For directly printing on glass or aluminum we advice user to apply glue-stick. A very thin layer will be sufficient to keep your print nicely in place. Another method is dissolving wood glue in water, you the consistency of the substance can be quite thin, a bit like milk. By applying just a few drops and smearing this out before you start heating the built plate will create a very thing layer which holds the woodFill down very well. If applying this method, be careful that you don’t get your electronics wet.

Another method that works well with colorFabb woodFill is polyimide tape, or Kapton tape. This tape is available as a very narrow strip or very wide strips which allow you to cover the build plate in one go. When the tape is applied correctly it can last for months.

TIP! Take your time leveling the bed and adjusting the the gap between 3d printer nozzle and build plate. A perfect first layer will is very important, especially for 3d prints with a large bottom layer. Having the nozzle set to close to the build plate will cause a pressure build up and as a result back flow in most hot ends.

TIP! PLA/PHA has very minimal warping tendencies, however if your printing parts which take up the maximum of you buildspace you might see some warping. If it’s very important that your part is perfectly flat than we suggest to turn down the fan that is cooling your part. This allows the material to slowly get rid of heat without warping. After a few centimeters you can turn on the cooling if the part needs it.

Material:

colorFabb woodFill - PLA/PHA + fine pinewood fibres

Diameter Tolerance:

± 0.05 mm

Density:

…

Glass Transition Temperature

55C