Our CarbonFil filament is based upon the unique PETG blend of our HDglass compound and is reinforced with 20% ultra-light and relatively long stringer carbon fibres, which has resulted in an exceptionally stiff carbon-fibre reinforced 3D printer filament. CarbonFil is twice as stiff as HDglass and yet it is even 10% more impact resistant, which is a remarkable feature for carbon-fibre reinforced filament.

Unique features

-

Reinforced with 20% ultra-lightweight and relatively long carbon fibre stringers

-

Extremely stiff

-

-

Great impact resistance

-

-

Very easy to print

-

-

Nearly warp-free, improved thermal stability, nearly perfect first layer and inter-layer adhesion

-

Good first layer adhesion to a heated glass print bed and many other surfaces

-

Heat deflection temperature of ± 85° C

-

Great dimensional stability

General printing guidelines *

| Nozzle size: ≥ 0.5mm |

Layer height: ≥ 0.3mm |

Flow rate: ± 100% |

| Print temp: ± 230 - 265° C |

Print speed: High |

Retraction: Yes ± 6mm |

| Heat bed: ± 0 - 60° C |

Fan speed: 50-100% |

Experience level: Beginner |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends and printer offsets that it is extremely difficult to give an overall one-size-fits-all setting.

Abrasiveness

Please be aware that CarbonFil filaments contain a relatively high concentration of extremely hard carbon fibres, which have an abrasive nature. In general these carbon fibres will accelerate the nozzle-wear of brass nozzles, much faster than unfilled filaments. We recommend to use nozzles from stainless steel or other hardened alloys.

Filament length

| ρ: 1.19 g/cc |

50 gr coil |

0.5 Kg spool |

2.3 Kg spool |

|

|

| Ø 1.75mm |

± 17.5m |

± 175m |

± 804m |

|

|

| Ø 2.85mm |

± 6.6m |

± 66m |

± 303m |

|

|

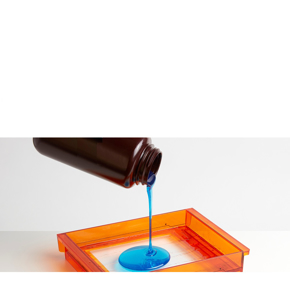

Nozzle cleaning

When printing with filled/composite filaments it is recommended to clean your nozzle immediately after printing by feeding 15-20cm PLA filament through your nozzle. This will make sure that any potential fillers are flown out of your nozzle. It is even better to use glow in the dark PLA as the extremely hard phosphorous particles are much more likely to scrape out residual waste from your nozzle.

Product export information

| HS Code: 39169090 |

Description: Monofilament |

Country of origin: the Netherlands |

Compliance *

This filament is compliant to below listed directives and regulations.

*) This declaration of conformity to directives and regulations is prepared according to our present standard of knowledge and may be amended if new cognitions are available and applies only for the above described products.