Shopping cart

Search

3D Printing Materials

Signal white RAL 9003

117,48 лв. / 60.07 €

A premium PLA filament, made in the color you want, on demand. Your product will be made within 5-8 business days, other stock products ordered will be shipped once the order is complete.

The color chart is used by colorFabb as a reference. We advise users to do the same when choosing a specific color. Our product images have been carefully made using the same lighting conditions and no post processing. However every screen will produce a slightly different color representation, therefor we do not recommend to base your choice on our product images alone.

Pure white RAL 9010

117,48 лв. / 60.07 €

A premium PLA filament, made in the color you want, on demand. Your product will be made within 5-8 business days, other stock products ordered will be shipped once the order is complete.

The color chart is used by colorFabb as a reference. We advise users to do the same when choosing a specific color. Our product images have been carefully made using the same lighting conditions and no post processing. However every screen will produce a slightly different color representation, therefor we do not recommend to base your choice on our product images alone.

Traffic white RAL 9016

117,48 лв. / 60.07 €

A premium PLA filament, made in the color you want, on demand. Your product will be made within 5-8 business days, other stock products ordered will be shipped once the order is complete.

The color chart is used by colorFabb as a reference. We advise users to do the same when choosing a specific color. Our product images have been carefully made using the same lighting conditions and no post processing. However every screen will produce a slightly different color representation, therefor we do not recommend to base your choice on our product images alone.

Traffic black RAL 9017

117,48 лв. / 60.07 €

A premium PLA filament, made in the color you want, on demand. Your product will be made within 5-8 business days, other stock products ordered will be shipped once the order is complete.

The color chart is used by colorFabb as a reference. We advise users to do the same when choosing a specific color. Our product images have been carefully made using the same lighting conditions and no post processing. However every screen will produce a slightly different color representation, therefor we do not recommend to base your choice on our product images alone.

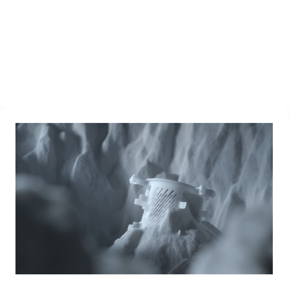

XT-CF20

117,48 лв. / 60.07 €

Our first special filament based on the Amphora 3D polymer. Reinforced with 20% specially sourced carbon fibers, this filament is perfect for parts which need high stiffness. XT-CF20 has a beautiful matte surface finish when printed.

CARBON FIBER IS ABRASIVE:

A special point of attention is the abrasive nature of the carbon fibers. In general these fibers will accelerate the nozzle-wear of brass nozzles, much faster than unfilled filaments. Therefore we recommend to use hardened steel nozzles.

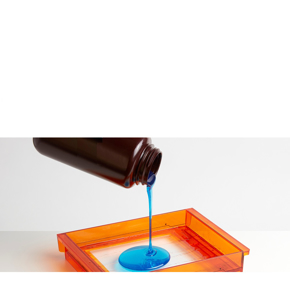

CORKFILL

93,96 лв. / 48.04 €

We're expanding our portfolio of natural filler for 3D printing filament with our latest corkFill. This filament has a lovely dark brown color and complements woodFill and bambooFill perfectly.

GLOWFILL

93,96 лв. / 48.04 €

This filament will literally make your work shine! During the day it’s a beautiful creamy color which prints to a perfect smooth finish. In the dark your prints will start to glow like you would not believe. A special highly concentrated phosphorescent pigment is matched with our PLA/PHA compound, so it’ll print just like our other PLA/PHA 3d printing filament. So charge up those 3d prints for some glow in the dark fun!

STEELFILL

104,00 лв. / 53.17 €

“Steel yourself”

With steelFill we are adding a fourth metal based 3D print filament to our portfolio after succesfully announcing bronzeFill in 2014, copperFill later that year and brassFill in early 2015. As with these other filaments, the key is post-processing and you can use similar techniques as with our other special metal based filaments.

BRASSFILL

141,00 лв. / 72.09 €

Experimental material.

The material is still in beta, which means we’re still working on the formulation to get the best possible performance. Our current formulation is providing excellent results on 1.75mm direct drive printers, such as the Makerbot Replicator 2 and Prusa I3.

The filament is slightly softer then bronzeFill and copperFill, users need to be careful with applying pressure onto the filament. We’ve found that 3D printers using a bowden tube set-up and 2.85mm filament gives the least reliable results. Users need to take extra care of not over stressing the filament, with pressure and retraction settings.

Like copperFill and bronzeFill the brassFill filament can be post processed. A unique quality of brassFill is the lovely golden shine it shows when polished to perfection.

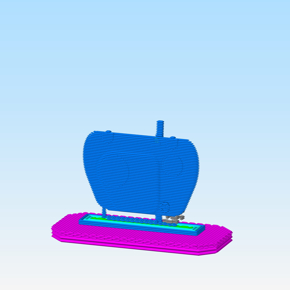

BRONZEFILL

106,00 лв. / 54.20 €

3d printing with metal on your own desktop 3d printer! This amazing one of a kind filament will allow you to print with actual bronze at home!

COPPERFILL

102,00 лв. / 52.15 €

3d printing with metal on your own desktop 3d printer! This amazing one of a kind filament will allow you to print with actual copper at home.

WOODFILL

93,96 лв. / 48.04 €

If you’re looking for something special in your filament portfolio then consider our woodFill filament. About 70% colorfabb PLA and 30% recycled woodfibres. Your prints will look absolutely amazing and your 3d printer cave will smell like a woodshop! Check out learn.colorfabb.com for a tutorial and slicer profiles on how to print with woodFill.

Berliner Luft

122,21 лв. / 62.48 €

BigRep True Berlin Color PLA is perfect for everything from prototypes to art projects, end user parts to rapid tooling applications. This filament extrudes very well between 190ºC and 225ºC and has very low moisture absorption.

Big Orange

122,21 лв. / 62.48 €

BigRep True Berlin Color PLA is perfect for everything from prototypes to art projects, end user parts to rapid tooling applications. This filament extrudes very well between 190ºC and 225ºC and has very low moisture absorption.

Schwarzfahrer

122,21 лв. / 62.48 €

BigRep True Berlin Color PLA is perfect for everything from prototypes to art projects, end user parts to rapid tooling applications. This filament extrudes very well between 190ºC and 225ºC and has very low moisture absorption.

Wannsee Blau

122,21 лв. / 62.48 €

BigRep True Berlin Color PLA is perfect for everything from prototypes to art projects, end user parts to rapid tooling applications. This filament extrudes very well between 190ºC and 225ºC and has very low moisture absorption.

Rotes Rathaus

122,21 лв. / 62.48 €

BigRep True Berlin Color PLA is perfect for everything from prototypes to art projects, end user parts to rapid tooling applications. This filament extrudes very well between 190ºC and 225ºC and has very low moisture absorption.

Mauer Grau

122,21 лв. / 62.48 €

BigRep True Berlin Color PLA is perfect for everything from prototypes to art projects, end user parts to rapid tooling applications. This filament extrudes very well between 190ºC and 225ºC and has very low moisture absorption.